Understanding PiggyBac Technology

PiggyBac is a type of transposon system originally discovered in the cabbage looper moth, Trichoplusia ni. Its name is inspired by the unique “hitchhiking” mechanism it uses to move around within the genome. PiggyBac transposons have been adapted for use in genetic engineering, where they serve as efficient vectors for introducing new genes into cells.

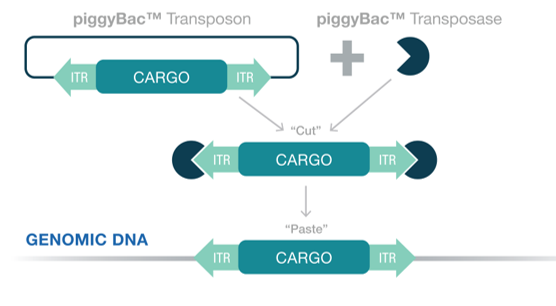

The piggyBac transposon system distinguishes itself by its capacity for “cut and paste” transposition, inserting itself into TTAA target sequences in the host genome with high precision. This process is seamless and leaves no footprint, making piggyBac an excellent choice for stable gene integration and expression.

How Does PiggyBac Work in Antibody Production?

Let’s break down the process:

Step 1: Constructing the Transposon Vector

In this initial stage, we create a PiggyBac transposon vector. This vector houses the crucial gene that dictates the production of the desired antibody. Also integrated within this vector is a ‘selectable marker’ gene, usually granting resistance to a particular antibiotic, which later plays a significant role in identifying cells that have been successfully transformed.

Step 2: Co-transfection into CHO Cells

Next, the PiggyBac transposon vector enters the CHO cells alongside another plasmid that expresses the PiggyBac transposase – the enzyme responsible for mobilizing the transposon. This co-transfection sets the stage for the PiggyBac system to work its magic.

Step 3: The Power of Integration

Once inside the CHO cells, the PiggyBac transposase identifies the transposon sequences around the antibody gene, disconnecting it from the plasmid DNA. Following this, the transposase ensures the integration of the transposon (with the antibody gene) into the CHO cell’s DNA, specifically at a TTAA sequence.

Step 4: Selecting the Transformed Cells

After allowing a recovery period for expression, the cells are treated with a specific antibiotic. Those cells that have successfully incorporated the transposon (and consequently, the antibiotic resistance gene) into their DNA are the survivors of this process.

Step 5: Clone Expansion and Testing

The surviving cells are cloned and cultivated. These clones undergo stringent testing to pinpoint those that efficiently produce the desired antibody.

Step 6: Achieving Large-Scale Antibody Production

Finally, a clone that demonstrates high levels of antibody production is identified and expanded for large-scale cultures. In these cultures, each cell – being a genetic replica of the others and possessing the stably integrated antibody gene – contributes to the production of the desired antibody.

Why Choose PiggyBac Over Transient Expression?

PiggyBac presents several advantages over transient expression when working with CHO cells:

Stability: PiggyBac integrates the gene of interest stably into the host cell genome, ensuring long-term expression, whereas transient expression often results in the loss of the gene after several cell divisions.

High Yield: PiggyBac outperforms transient systems by potentially providing higher yields, thanks to each cell possessing the integrated gene and contributing to antibody expression.

Scalability: PiggyBac supports the creation of large populations of genetically identical cells – an attribute vital for large-scale therapeutic protein and antibody manufacturing.

Flexibility: The ability of PiggyBac to incorporate large DNA sequences permits researchers to insert complex genetic constructs, useful for producing advanced antibodies.

Long-term Cultivation: Stable cell lines are favored for prolonged culture and commercial production, an area where transient expression falls short.

In Conclusion

While transient expression may suit certain applications, such as quick protein production for initial testing, the PiggyBac transposon system emerges as a superior, sustainable, and efficient choice for long-term, large-scale antibody production in CHO cells. Explore this exciting frontier of biotechnology and enjoy the benefits of this ground-breaking tool today!

Our Gene Editing Technology

Hera’s cutting-edge piggyBac gene delivery technology and Cas-CLOVER site specific nuclease are an ideal combination for tackling your most challenging cell line engineering projects whether it is reporter cell lines, custom assays, or Cell Line Development. Learn more about these technologies by clicking the links below.